Exactly How an Optical Fibre Diameter Analyser Improves High Quality Control in Fibre Production

The integration of an Optical Fibre Diameter Analyser into Fibre manufacturing processes stands for a significant innovation in high quality control approaches. By providing real-time, precise measurements of Fibre diameters, this innovation deals with the essential requirement for consistency in production criteria.

Significance of Fibre Diameter Measurement

Accurate dimension of Fibre Diameter is essential in the area of optical Fibre innovation, as it directly affects the efficiency and integrity of Fibre optic systems. The Diameter of an optical Fibre impacts its light-carrying ability, depletion, and total transmission performance. Precision in gauging Fibre Diameter ensures that the optical buildings are kept within specified tolerances, which is vital for optimal signal honesty.

Variants in Fibre Diameter can cause increased losses as a result of spreading and modal dispersion, affecting the quality of data transmission. In high-speed interaction systems, such discrepancies can lead to considerable destruction of signal top quality, resulting in information errors and reduced performance. Furthermore, constant Fibre Diameter is vital for compatibility with connectors and splicing technologies, which are indispensable components of Fibre optic networks.

Quality assurance processes in Fibre production greatly rely upon accurate Diameter dimensions to ensure conformity with sector requirements. By applying robust dimension strategies, suppliers can improve item dependability, lessen waste, and improve general system performance. Thus, the relevance of Fibre Diameter dimension can not be overemphasized, as it works as a cornerstone in the innovation of optical Fibre technology and its applications in modern-day interaction networks.

Just How the Analyser Works

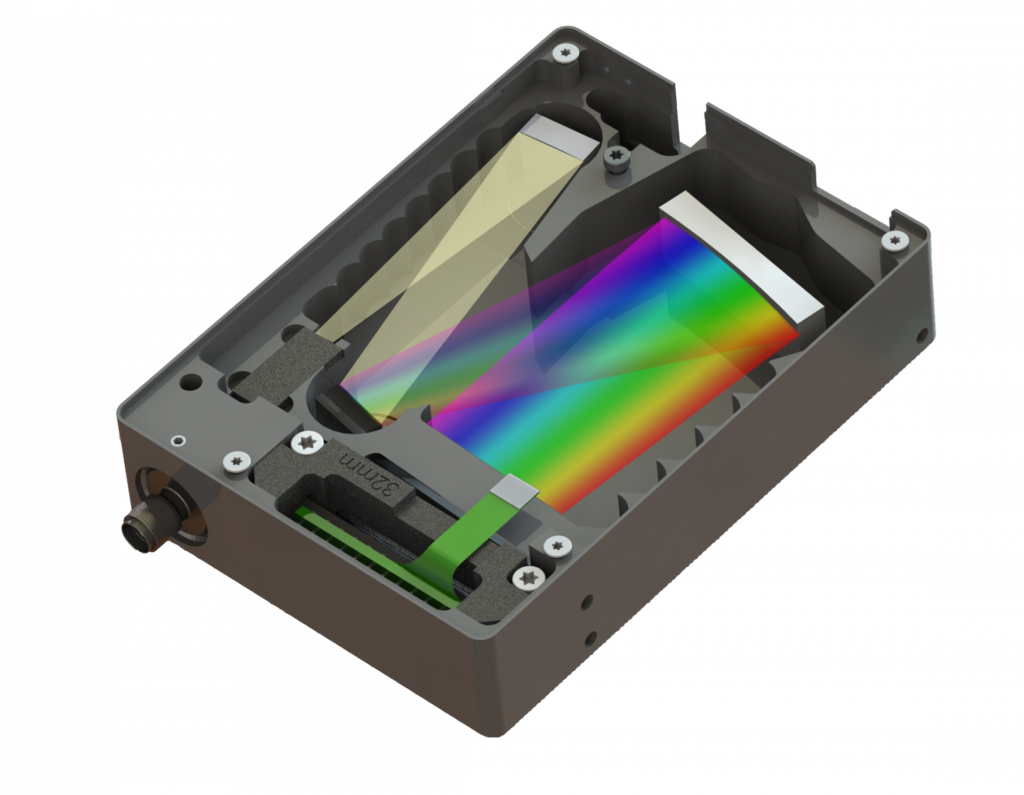

The efficient dimension of Fibre Diameter counts on advanced analytical techniques that ensure accuracy and integrity in optical Fibre production (optical fibre diameter analyser). The Optical Fibre Diameter Analyser utilizes a mix of laser modern technology and progressed image processing formulas to properly examine the Diameter of fibres as they are produced

Initially, a laser beam is guided at the moving Fibre, creating a cross-sectional shadow. The analyser records this darkness utilizing high-resolution cams positioned tactically along the assembly line. The captured photos are after that processed in real-time to figure out the Fibre's Diameter with remarkable precision.

The system makes use of sophisticated formulas that make up numerous elements, consisting of variants in light intensity and ecological conditions, to boost measurement integrity. It can find minute changes in Diameter, such as fluctuations that may take place during the manufacturing procedure.

Moreover, the analyser is capable of dealing with several fibres at the same time, raising throughput without endangering precision. By offering immediate feedback on the Diameter, the Optical Fibre Diameter Analyser plays a vital role in maintaining strict quality assurance requirements, making sure that the final item meets industry specs and consumer demands.

Advantages of Real-Time Monitoring

While typical techniques of checking Fibre Diameter often include lengthy post-production checks, real-time surveillance significantly improves the effectiveness and quality of optical Fibre manufacturing. optical fibre diameter analyser. This aggressive technique permits producers to recognize inconsistencies in Fibre Diameter as they happen, as opposed to waiting up until manufacturing is Learn More Here full to analyze quality

By constantly measuring the Diameter throughout manufacturing, manufacturers can guarantee that the fibres fulfill strict specs, leading to reduced irregularity and improved consistency. Real-time monitoring likewise allows instant rehabilitative activities to be taken, decreasing waste and avoiding malfunctioning fibers from entering the supply chain.

In addition, this modern technology promotes boosted data collection and evaluation, giving understandings right into manufacturing patterns and prospective areas for improvement. Such data-driven decision-making encourages suppliers to maximize processes and preserve high standards of quality assurance.

On top of that, real-time surveillance cultivates a society of continuous renovation within the production setting. Staff members are much more involved when they can see the influence of their operate in real-time, bring about increased responsibility and a commitment to quality. On the whole, the implementation of real-time tracking systems in optical Fibre manufacturing translates to remarkable item high quality and raised consumer satisfaction.

Effect On Manufacturing Efficiency

Carrying out optical Fibre Diameter analysers considerably improves production efficiency by simplifying the manufacturing process. These tools promote constant monitoring of Fibre Diameter, enabling producers to spot deviations in real-time. By identifying disparities without delay, assembly line can be readjusted quickly, lessening downtime and minimizing the possibility of creating faulty products.

Furthermore, the combination of these analysers right into the manufacturing process makes it possible for far better resource allotment. With accurate Diameter dimensions, operators can maximize product use, ensuring that resources are not lost on flawed fibers. This precision likewise contributes to less rework and junk, ultimately reducing production prices.

The automation provided by optical Fibre Diameter analysers reduces dependence on manual examinations, which are prone and commonly time-consuming to human mistake. As a result, staff members can concentrate on even more tactical jobs, enhancing general productivity.

Additionally, the information generated from these analysers can notify procedure renovations and help with better decision-making. By evaluating patterns in Fibre Diameter variations, suppliers can execute aggressive measures to improve manufacturing techniques and preserve constant top quality. In summary, optical Fibre Diameter analysers play an essential role in improving manufacturing efficiency, resulting in better output and enhanced earnings.

Instance Researches and Success Stories

Across different markets, study check this site out highlight the transformative impact of optical Fibre Diameter analysers on production processes. One popular example is a leading telecoms business that encountered obstacles with irregular Fibre sizes, leading to increased rejection rates. By integrating an optical Fibre Diameter analyser, the firm attained real-time surveillance of Fibre measurements, causing a 30% decrease in issues and substantial price financial savings.

Furthermore, a study organization concentrating on sophisticated products used optical Fibre Diameter analysers to improve their experimental procedures. The analyser's ability to provide comprehensive understandings into Fibre uniformity allowed the growth of ingenious products with go to this website improved efficiency characteristics.

These success tales underscore the necessary duty of optical Fibre Diameter analysers in enhancing quality assurance, improving production performance, and driving development throughout varied industries.

Verdict

In verdict, the Optical Fibre Diameter Analyser plays a crucial duty in boosting top quality control within Fibre manufacturing. As shown with different situation research studies, the analyser shows vital for accomplishing remarkable item high quality in Fibre manufacturing.

The implementation of optical Fibre Diameter analysers enabled for strict top quality control, guaranteeing that the generated fibers satisfied exacting sector criteria.In verdict, the Optical Fibre Diameter Analyser plays an essential duty in improving high quality control within Fibre manufacturing.